TN VALLEY AGRICULTURE AND OUTDOORS: Limestone gin manager sees bright future ahead

Published 9:00 am Sunday, March 24, 2019

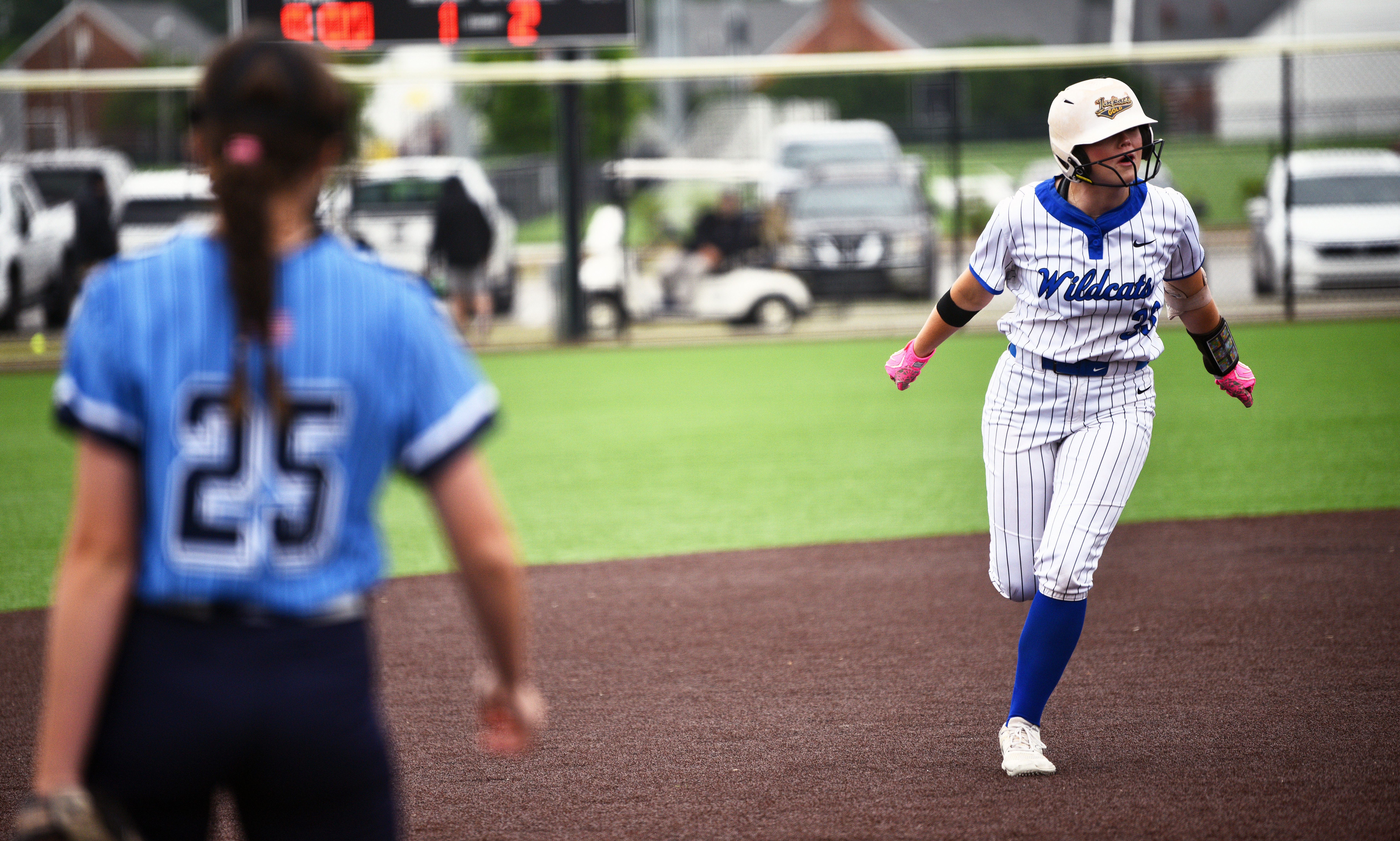

- Billy Sickler, manager of Limestone County’s Associated Growers Cooperative cotton gin, explains how cotton is pressed through the teeth in this machine to remove the seeds, which are ground up and fed to dairy cattle.

A manager at Limestone County’s newest cotton gin says Alabama is still in the running to become the cotton king like it was in the olden days — well, from 1979 to 2007.

Billy Sickler, manager of Associated Growers Cooperative gin, says the new 25,000-square-foot gin is holding her own and then some.

With one cotton season now behind her, the gin has dried and ginned 7,833 pounds more cotton in 2018 than in 2017. The old gin processed 34,607 bales of cotton in 2017 and the new gin processed a whopping 42,440 bales in 2018. Sickler is hoping the gin will process 50,000 to 60,000 bales this coming season. The new gin also did the work in half the time it used to take at the old gin.

In the 2017 season, it took about five and a half months to do the drying and ginning. This past year, it took only about two months — from Oct. 27 to Dec. 30, 2018 — to do the work.

The crop delivered decent money to its farmers. Cotton averaged about 75 cents a pound for a 500-pound bale this season, though the price shot up to 90 cents per pound at one point and later down to the upper 60s, Sickler said.

The value of cotton is based on its length, strength, micronaire (fiber fineness and maturity), length uniformity, color and leaf grade. The United States Department of Agriculture classes every bale after it is ginned. The class determines the price of the cotton.

Water was a problem for the 2018 crop. Much of the crop was still damp from rain when it was harvested, which meant it had to dry before it could be ginned, Sickler said.

“The cotton was extremely wet last year,” he said.

Sickler said the gin uses four 8-million-BTU burners from Samuel Jackson Inc. in Lubbock, Texas, to dry the cotton.

Left over from the ginning process are the cotton seeds, which are ground into meal for dairy cattle, and the motes, which are used in making paper money and other products.

Fast advantage

AGC started building the new $7.4 million gin June 1 last year. The work included about $1 million in new electronics and technology, plus the ability to double the previous gin’s baling capacity, Sickler said.

The work was completed in October, just in time for the 2018 cotton crop. Cotton season for the gin runs from middle September to about Christmastime.

The 2017 crop took longer to gin than the 2018 crop. This past year, it took only 65 days to dry and gin the cotton crop, Sickler said. In 2017, it took 137 days. At top speed, the new gin can produce 60 bales per hour, but the Growers run it at 45 to 50 an hour. The speed and efficiency means they cut the labor cost of producing a bale from $14 to $7 per hour.

The speed gets the ginning done quicker, but it generates some whopping monthly utility bills along the way. The biggest monthly bill AGC produced was $158,000.

Sickler had expected the bills to increase to about $70,000 per month. But because drying and ginning now takes fewer man hours, those stouter bills are offset by the savings, he said.

Having a much quicker ginning process also means farmers can get paid for their crops around the first of the year rather than in March, which had been the case, Sickler said.

With commodity prices for soybeans and corn falling and quicker processing at the new gin, Sickler hopes more Limestone County farmers will consider planting cotton in the coming years. It could put Limestone County back in the running for cotton king.